Winter weather isn’t something we have to think about too much here in Georgia. However, from time to time we do see a freezing rain shower or light snow fall come in. Road treatments, such as rock salt, are commonly used to melt frozen ice and provide traction for drivers. This makes roads safer to traverse. However, winter road treatments also have a significant impact on commercial asphalt, and understanding their effects is crucial for maintaining the longevity of your pavement. Here’s what you need to know.

How Winter Road Treatments Damage Asphalt Surfaces

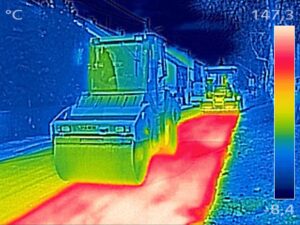

Winter road damage often occurs due to the use of de-icing salts and chemicals, which are intended to melt snow and ice. However, these substances can have detrimental effects on asphalt surfaces over time. The repeated application of salt and de-icing chemicals can lead to accelerated deterioration of the asphalt surface, causing cracks, potholes, and weakening of the pavement structure. The presence of water from melting ice can also seep into existing cracks in the asphalt, leading to further damage when it freezes and expands. This cycle of freezing and thawing can exacerbate road damage, creating an increased need for costly repairs and maintenance. Additionally, the impact of heavy vehicles on treated asphalt during winter can worsen the structural integrity of the pavement.

The Ecological Impact of Winter Road Treatments

Winter road treatments can have a significant environmental impact that often goes unaddressed. The runoff from de-icing chemicals used on roads can seep into the surrounding soil and bodies of water, causing contamination and harm to local ecosystems. As businesses increasingly prioritize environmental responsibility, it’s crucial to explore alternative methods or less harmful products for winter road treatments that can achieve similar results while minimizing negative consequences on the environment.

Managing the Effects of Winter Road Treatments

Ice treatment on commercial asphalt can lead to serious road damage if not properly managed. To minimize these effects, it’s important to consider several factors. First, using de-icing products that are less harmful to asphalt can help reduce the impact of winter treatments. Additionally, regular inspection and maintenance of the asphalt surface before and after winter is crucial to identify any potential damage early on. Implementing proper drainage systems can prevent water from pooling and freezing on the asphalt, reducing the need for excessive ice treatment. It is also important to plow and remove snow regularly to avoid the build-up of ice on the surface. Applying a sealcoat before winter sets in can provide an added layer of protection against ice treatment damage. Finally, investing in high-quality materials for asphalt construction and repair can improve its durability in harsh winter conditions, reducing the need for excessive ice treatment.

Conclusion

By understanding the full scope of winter road treatments’ effects on commercial asphalt, businesses can make informed decisions about maintenance strategies that prioritize both pavement integrity and environmental responsibility. It is imperative to explore sustainable alternatives that reduce long-term damage while effectively managing winter safety concerns. This proactive approach will not only benefit your business but also contribute positively to your community’s environmental health.

Call Georgia’s Wildcat Pavement for High-Quality Asphalt Maintenance and Repairs

At Georgia’s Wildcat Paving, we offer professional asphalt services to maintain, treat, and repair pavement that’s been affected by winter weather and other wear and tear. We can help you avoid greater damage using our expert knowledge and high-tech tools. Don’t wait until damage becomes too severe to fix! Give us a call or fill out our online form to get a free quote today.